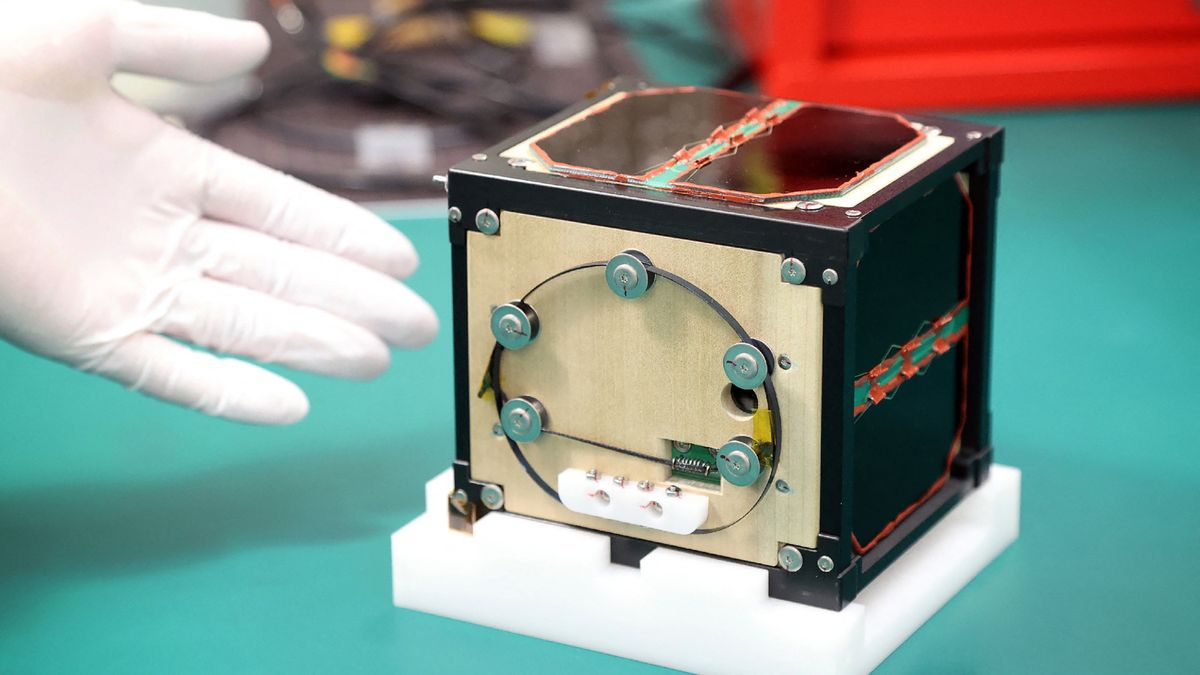

The world’s first wooden satellite, LignoSat was designed by a team of scientists from Kyoto University in Japan. Sumitomo Forestry, a leading Japanese logging company collaborated in its creation.

Also Read: Shenzhou-18 News: China’s Astronauts Return to Earth After Six-Month Mission

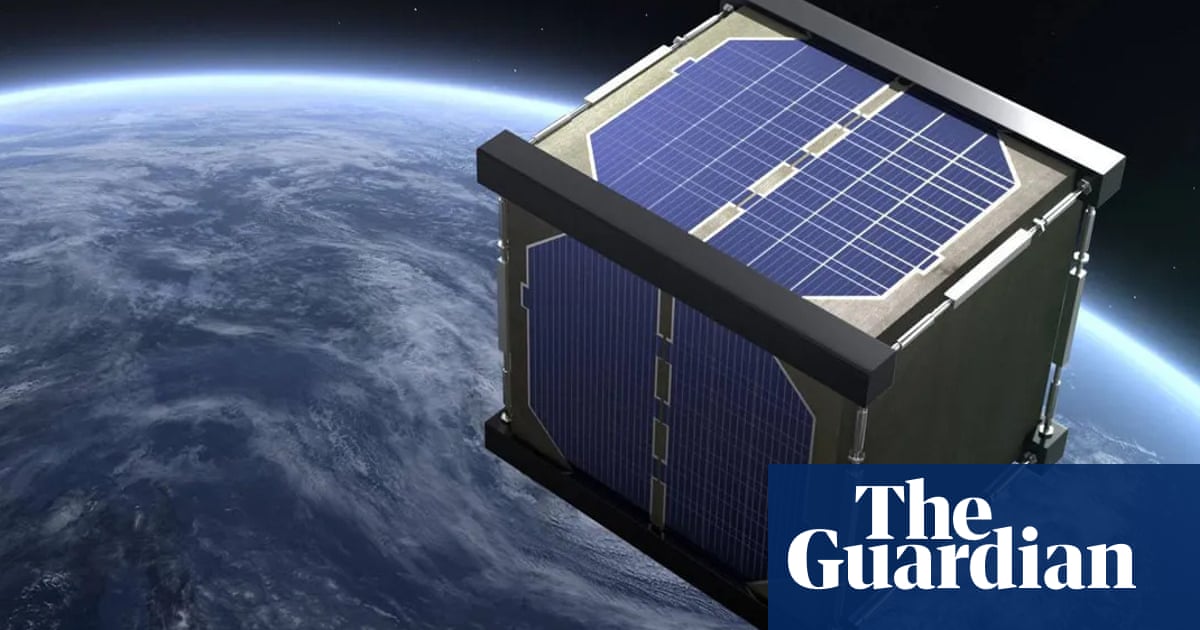

LignoSat aims to showcase wood as a viable material for space applications particularly for satellites. Unlike traditional aluminum satellites that burn up and release harmful particles into the atmosphere, LignoSat is designed to minimize environmental impact, as it would generate minimal pollutants upon re-entry.

If successful, this wooden satellite could help set a new standard for eco-friendly satellite design, minimizing space pollution.

LignoSat is remarkable for being assembled without the use of screws or glue, following traditional Japanese craftsmanship techniques.

This wooden satellite relies solely on precise interlocking mechanisms. This design also enhances the durability of the satellite by eliminating weaknesses from screws or adhesives, which can corrode or deteriorate under the extreme conditions of space.

As the number of satellites in Earth’s orbit increases, so does the volume of space debris. This is an urgent issue with the rise of mega-constellations like SpaceX’s Starlink network.

Unlike metal satellites, which create oxide particles during atmospheric re-entry, wooden satellites are expected to burn up completely, releasing fewer pollutants.

This reduction in space junk would benefit telecommunications and reduce harmful particles that can impact Earth’s atmosphere.

Before LignoSat’s construction, researchers conducted a 10-month test on the ISS to determine the durability of different types of wood in space.

Honoki emerged as the most suitable option due to its resistance to extreme temperatures and radiation.

These tests helped ensure that LignoSat’s wooden structure could endure the harsh space environment, which fluctuates from -100 to 100 degrees Celsius every 45 minutes.

Honoki wood sourced from the magnolia tree is known for its lightweight strength and resistance to degradation. These properties make honoki an ideal material for enduring the vacuum of space, where moisture and oxygen are absent, which prevents wood from rotting or burning.

Researchers believe that timber could one day be used for interplanetary construction including habitats on Mars and the Moon, allowing humans to live and work in space indefinitely.

LignoSat represents more than just a satellite experiment. Takao Doi, a professor at Kyoto University and a former astronaut envisions timber being used on Mars or the Moon within the next 50 years.

LignoSat’s mission is around testing wood’s resilience and durability in space, which involves monitoring how magnolia wood handles cosmic radiation, temperature fluctuations and the vacuum of space.

The satellite will orbit Earth for six months, collecting data on the performance of wood compared to conventional metal-based satellite components.

Also Read: News About Extinction: Scientists Predict Human and Mammal Extinction

Magnolia wood was chosen for its strength, resilience and low density. The magnolia wood used in LignoSat’s panels was processed using an ancient Japanese technique that avoids screws and glue.

Researchers hypothesize that wood might prove even more durable in space than on Earth because it lacks exposure to water and oxygen, which are causes of wood degradation on Earth.

The launch of LignoSat serves as a landmark for sustainable satellite manufacturing. If successful, this mission could make the way for using biodegradable materials in the construction of satellites, which could reduce space debris.

Utilizing wood, a renewable resource aligns with global sustainability goals. This mission exemplifies how technological advancements can integrate environmentally friendly materials, reducing the environmental footprint associated with satellite launches.

As satellite launches continue to increase, the problem of space debris has become more pressing. Traditional satellites often have metal components that survive re-entry.

LignoSat’s wooden structure is designed to burn up completely upon re-entry, leaving no metallic remnants in the atmosphere and thus helping to tackle the space junk problem.

If wood proves viable, future wooden satellites could eliminate a portion of the debris left by traditional materials reducing risks for other space missions and the International Space Station.

Throughout its six-month mission, LignoSat will be subjected to extreme environmental factors such as cosmic radiation, temperature swings and microgravity, with on-board sensors continuously recording how the wood responds.

Researchers will analyze structural integrity, resilience and temperature sensitivity of the wood over time, assessing its capability to handle these stresses compared to metals.

This testing phase is important for evaluating the potential of wood in spacecraft and habitats on the Moon or Mars, where extreme conditions are similarly prevalent.

Wood has been used in aviation and aerospace before, early 1900s airplanes relied on wooden construction.

In past space missions, wood-based materials like cork have been employed as a heat-resistant layer on spacecraft shells during atmospheric re-entry.

The Soviet Union and Russian lunar landers even used cork for added traction during descent.

Also Read: Asteroid Apophis will Pass Extremely Close to Earth in 2029